Servo Motor Repairing

Pick and drop of your items to be repaired

We can pick your repair items up from anywhere

Free

Evaluation

Send your part to us for a Free Evaluation

Enquire today for Free Repair Quotation

Enquire today for a free no obligation quote

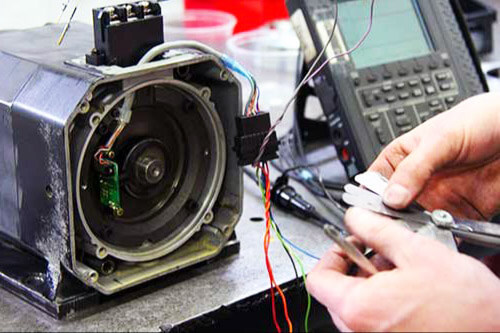

Servo Motor Repairing from Shawa

Shawa servo motor repairing workshops in-house machinist and custom built test rigs have been designed to provide our customers with the very best servo motor repair service possible. We specialise in repairing motors from a broad range of manufacturers, therefore you can be safe in the knowledge we have the expertise to repair your faulty servo motor, no matter who manufactured the part. All our servo motor repairs come with the added security of 6 months whole of unit warranty.

Our team of skilled motor engineers can repair a wide range of motors including:

How does the Servo Motor Repairing service work?

Your servo motor will go through a rigorous inspection, repair and testing process. The below list highlights some of the processes involved:

-

Servo Motor initially inspected for obvious mechanical damage to electrical connectors, fixings and the drive shaft.

-

Various electrical tests completed on servo motors including an AC drop test and insulation resistance (IR) testing to ensure that servo motor windings are in good working order.

-

Insulation resistance is temperature-sensitive, when the temperature increases, insulation resistance decreases (If the windings appear short then servo motor to be rewound).

-

The feedback devices to be tested as appropriate. Tacho to be drop tested, resolver and encoder tested using Mitchell Rig.

-

Our Mitchell Rig allows us to ascertain the correct lockup angle relationship of the feedback device to the servo motor windings.

-

Servo motors dismantled down to their component parts, casing to be sandblasted (if required), jet-washed and then stoved to ensure that all contaminates are removed from both the internal and external parts of the motor.

-

Over time too much or too little lubrication creates heat through pressure or friction and this can create noise, meaning that the bearings have failed.

-

New bearings and oil seals fitted as part of the service to improve the servo motors life cycle.

-

On completion of the service we spray paint the motor.

-

To ensure servo motors run correctly on-site, testing at various speeds is undertaken to test functionality

Servo Motor Repairing Lead Times

We pride ourselves on the quality of our motor repair service and understand the effect a faulty machine has on our customer’s production. This is why we have a number of servo motor repair options to suit your requirements:

Standard Electronic Repairs

Up to 10 workings days*

Emergency Electronic Repairs

Up to 3 working days.*

*Subject to parts and availability

In house Machinist

Our motor workshop includes an in-house Machinist for manual Milling and Turning so we can offer a complete machining and motor repair service along with balancing, rewinds and re-banding.

Motor Workshop

Shawa dedicated motor workshop is designed to meet all our customers repair needs.

Servo Motor Engineers

Our experienced servo motor engineers repair all makes and models of motors.

Custom Built Test Rigs

At Shawa, we have a huge array of custom build test rigs to fully functionally test your equipment.

What Are The Benefits?

State of the Art Workshops

Our workshops and custom built test rigs have the latest technology.

Experienced Engineers

Our highly skilled engineers are equipped to repair a broad range of parts.

Emergency Repairs

We can repair your faulty part within 3 working days*

International Sales Team

Speak to one of our sales representatives in your language.

6 Month Warranty

All repairs come with a 6 month free warranty

call us:

+91 – 9870100205

OR

request a callback today and

we will call you back shortly